MicroVFD is QPT’s high-frequency (1MHz) low-voltage solution targetted at the robotics and cobot market. The solution enables greater control and efficiency with lower system complexity and cost, providing significant benefits in the fast-growing cobot market.

MicroVFD utilises our qControl technology to generate 1MHz PWM with picosecond accuracy. Our tiny output filters (qFilter) deliver a pure sine voltage and our internal high-frequency current & voltage sensing (qSense) combine to enable MicroVFD to deliver smoother movement, dynamic correction for torque cogging and allows the motor drive itself to provide high-fidelity sensing. This is achieved without expensive external sensors or encoders, improving performance and significantly lowering costs.

SYSTEM Benefits

Dynamic Torque Ripple & Cogging Correction

Real-time compensation using our integrated qSense technology, detecting voltage and current disturbances in the time and frequency domains thanks to the very high signal-to-noise ratio of a sine wave drive. This drastically outperforms far more expensive encoder-based static methods which drift over time and cannot react dynamically in real time to changes in the delivered torque.

Unprecedented Precision and Smoothness

Our qControl technology is capable of generating the 1MHz signals with picosecond accuracy. The tiny filters deliver true sine voltage enabling cleaner control signals, delivering smoother motion critical for delicate assembly and medical robotics.

High-Fidelity Sensorless Diagnostics

Clean sine wave output supports advanced torque and vibration monitoring for advanced sensing and predictive maintenance. The motor drive itself is able to detect and report on the exact cause of any vibrations in the system, all without the need for expensive external sensors.

Compact, Lightweight Integration

1 MHz switching dramatically reduces filter and drive size, enabling the motor drives to be fully integrated with the motors in the robotic joints.

Lower System & Development Costs

With the integrated filters, expensive shielded cabling is not required. EMC is also much simpler, motor life is extended, expensive encoders and sensors can be removed, and much higher performance can be achieved from cheaper motors.

AI enabled for next-generation designs

MicroVFD lays the foundation for local AI processing to further improve the performance of each motor, and a cloud-based solution to monitor and optimise across a fleet of electric motor systems, such as an entire production line of machine tools or robots.

MICROVFD ARCHITECTURE

MicroVFD technical specifications

Datasheet is available under NDA. Please contact us for further details.

MicroVFD combines QPTs propriatary qControl, qSense and qFilter to enable 1MHz hard-switching, filtering of all EMI and delivering a pure sine voltage output to the motor. A full architecural block diagram is available under NDA. Please contact us for further details.

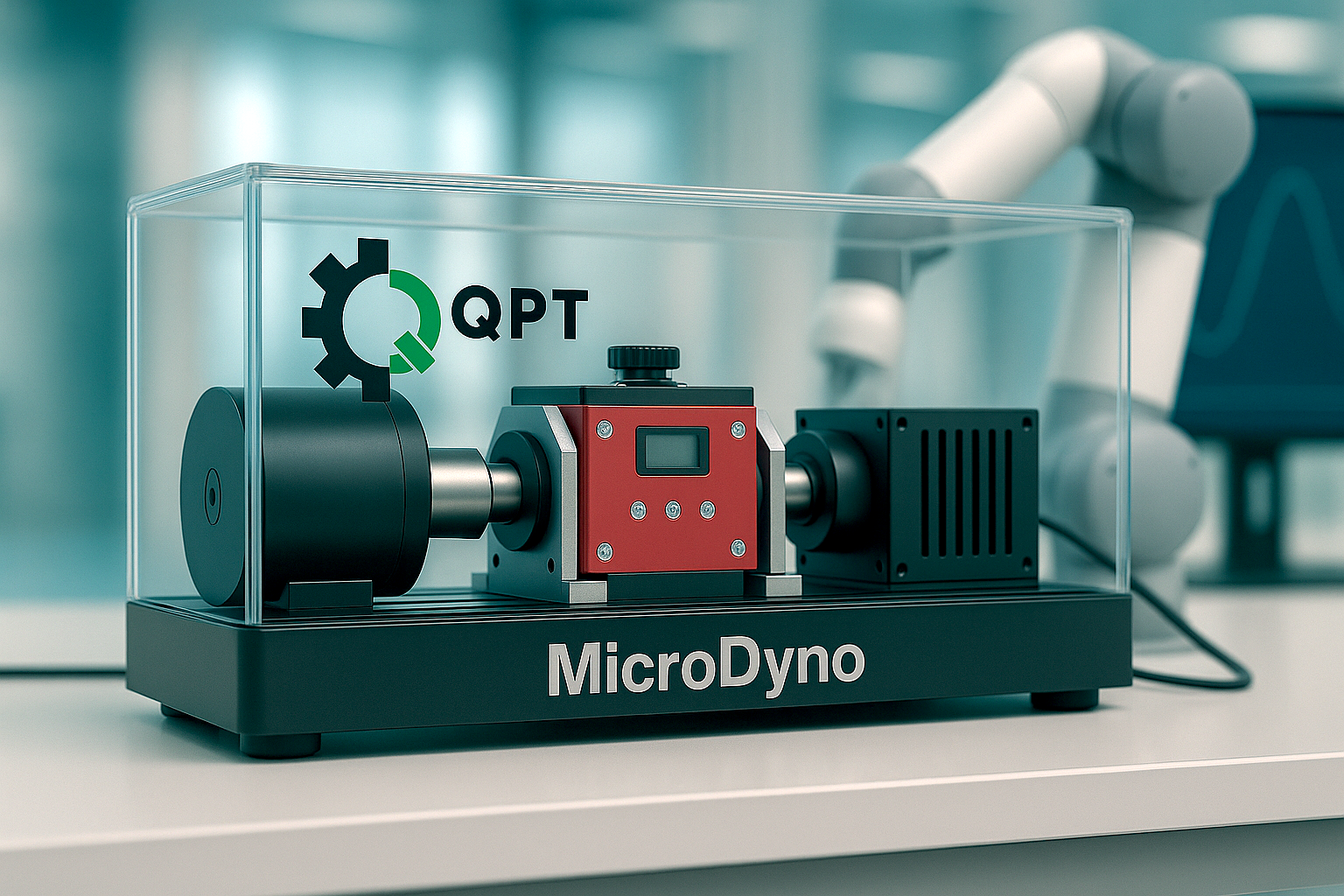

INTRODUCING THE MicroDYNO Test PLatform

Our MicroDyno test platform is a portable testing system for MicroVFD. This fully modular system allows us to demonstrate the benefits of MicroVFD. If required we can also arrange bespoke testing to show the benefits on specific motors.

If you would like a demonstration of the MicroDyno test platform, please contact us for further details.

CORE APPLICATION AREAS FOR MICROVFD

Collaborative Robots

Our MicroVFD solution enables greater control and efficiency with lower system complexity and cost, providing significant benefits in the fast-growing cobot market.